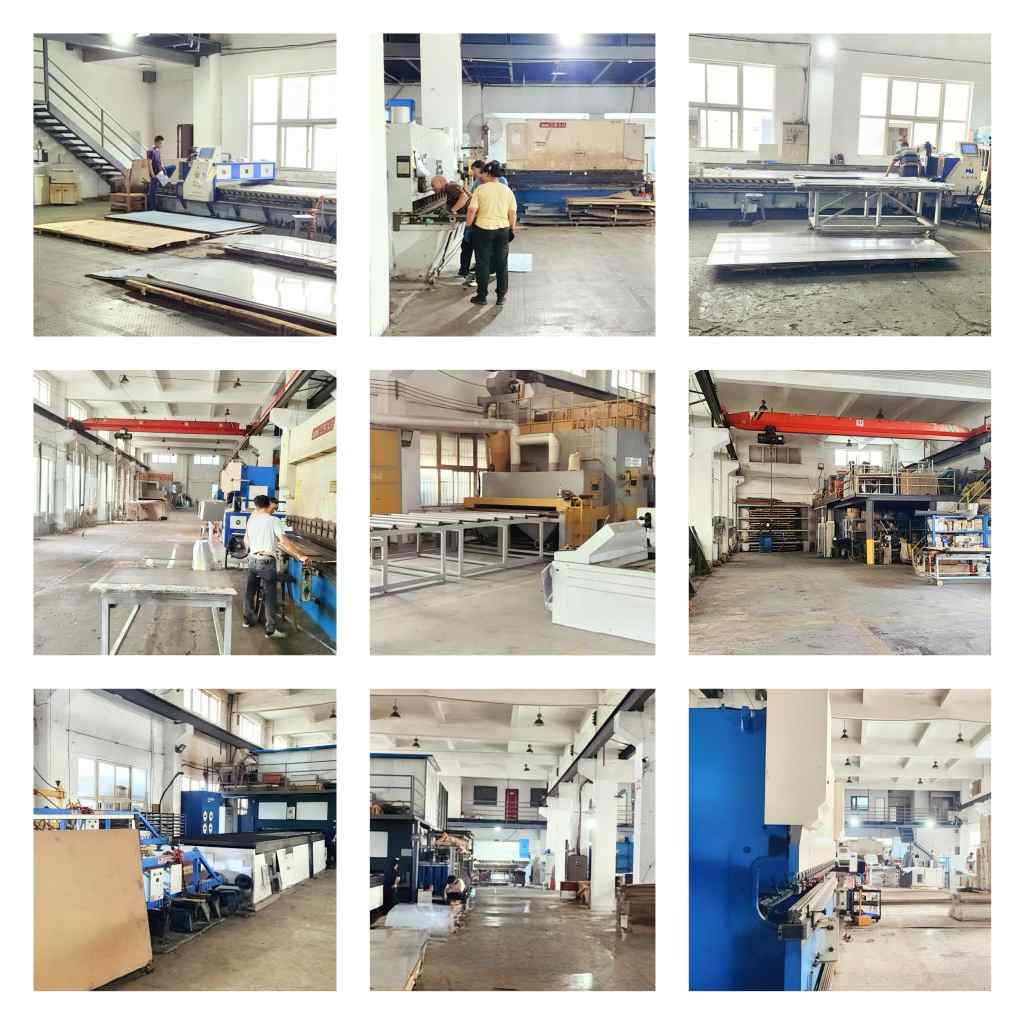

Factory Tour

Metal Fabrication Workshop

Our metal fabrication workshop is equipped with advanced CNC machines, laser cutting systems, and precision welding facilities, ensuring high-quality production of metal elevator shells, decorative wall panels, partitions, and custom shelving. With a skilled engineering team and strict quality control, we deliver durable, precise, and innovative metal solutions for both architectural and commercial applications.

Advertising & Event Display Workshop

Our advertising and event display workshop specializes in professional printing and fabrication of banners, roll-up stands, fabric flags, lightboxes, and exhibition backdrops. With high-resolution digital printers, UV technology, and specialized finishing equipment, we guarantee vibrant colors, sharp details, and durable display products—perfect for branding, events, and promotional campaigns worldwide.

Surface Finishing Options in Sheet Metal Fabrication

Surface Finishing Options in Sheet Metal Fabrication

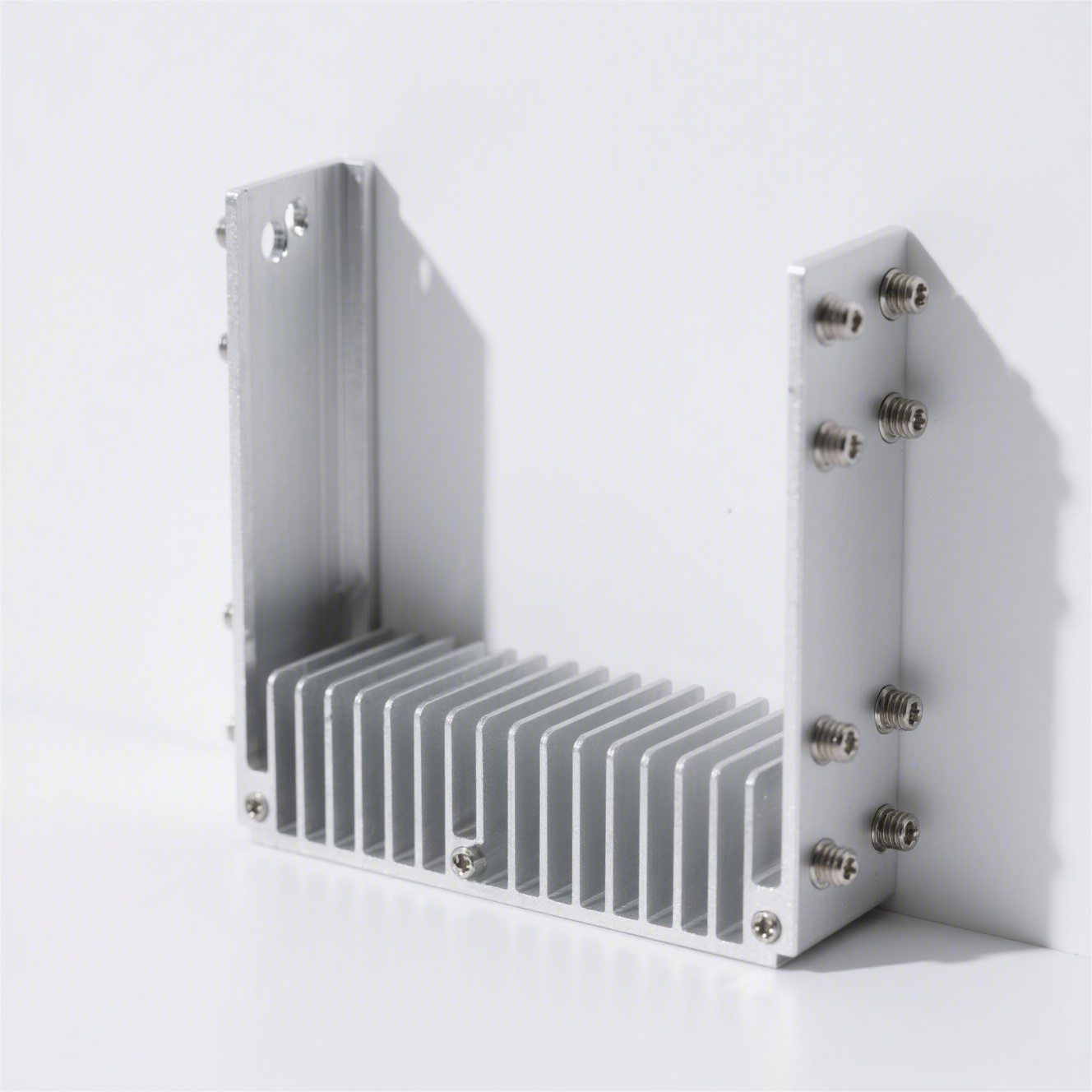

CNC Precision in Sheet Metal Fabrication

CNC Precision in Sheet Metal Fabrication

Your Trusted Partner in Sheet Metal Fabrication

Your Trusted Partner in Sheet Metal Fabrication