About Us

Brushed vs Mirror Finish vs Powder Coating – Which to Choose?

Views : 431

Update time : 2025-09-23 15:37:23

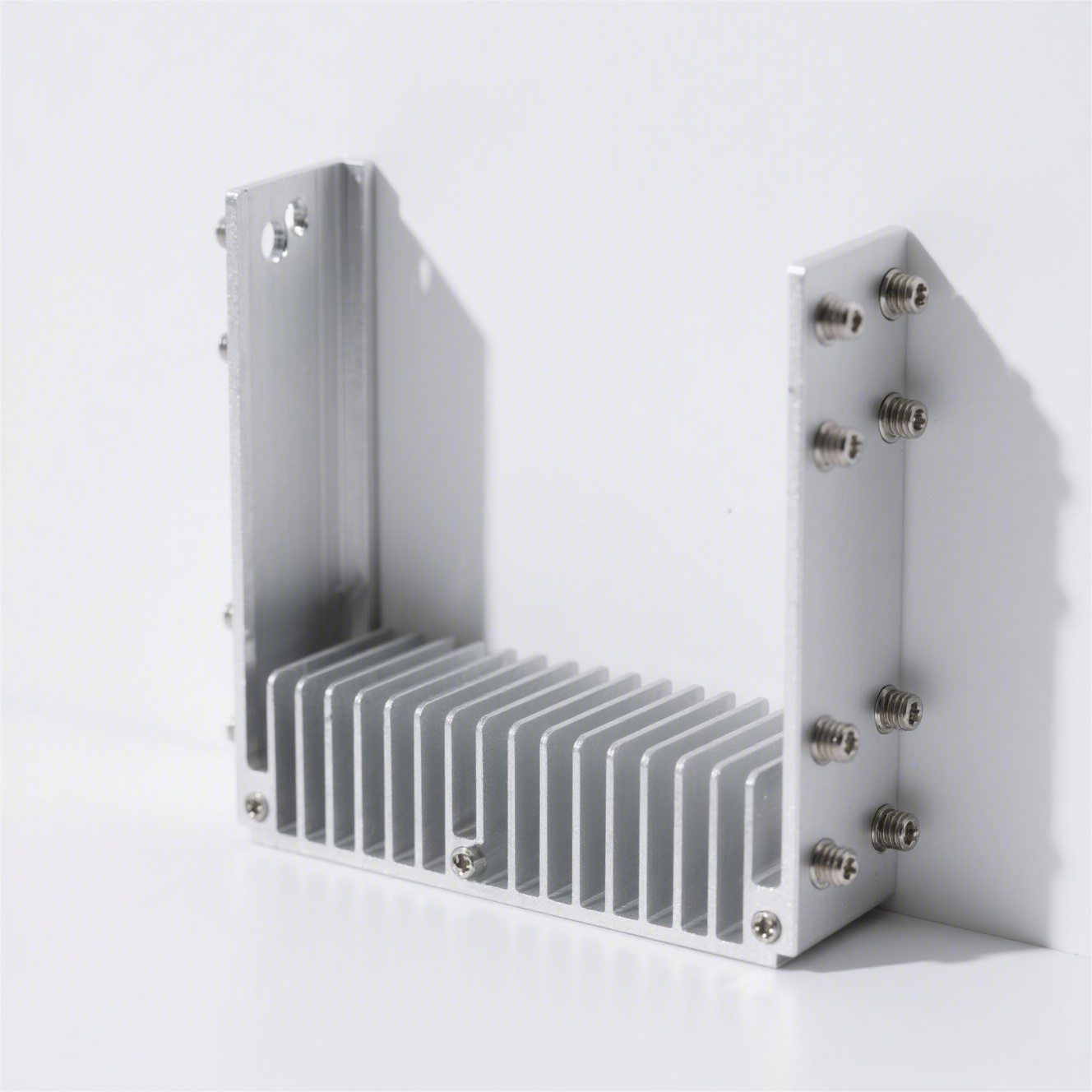

When it comes to sheet metal fabrication, selecting the right surface treatment is crucial for both performance and appearance. At JOCHARMSTEEL, we provide multiple options to meet your specific needs:

Brushed Finish: Best for projects requiring a clean, modern, and scratch-resistant look.

Mirror Finish: Perfect for high-end decorative applications where shine and reflection matter.

Powder Coating: Durable and weather-resistant, making it the ideal choice for outdoor and industrial use.

Each finishing method has unique advantages, and the right choice depends on your application environment, durability needs, and design preferences.

https://jocharmsteel.com/Contact JOCHARMSTEEL now for expert advice on the best surface treatment for your project.

相关新闻

Surface Finishing Options in Sheet Metal Fabrication

Surface Finishing Options in Sheet Metal Fabrication

Sep 06,2025

Surface finishing is essential in sheet metal fabrication, not only for aesthetic appeal but also for durability and protection. At JOCHARMSTEEL, we offer a wide range of metal surface treatment options to suit different project requirements:

Brushed Finish (Brushing): Creates a matte, textured look, ideal for industrial and modern designs.

Mirror Polishing: Produces a high-gloss reflective surface, often used for decorative or luxury applications.

Powder Coating: Provides excellent resistance to corrosion and scratches, available in multiple colors.

Electroplating: Adds extra durability and improves resistance against wear and oxidation.

Choosing the right surface finishing process depends on both function and appearance. For example, brushing is often used in appliances, while powder coating is best for outdoor structures.

Get in touch today to learn which finishing option best suits your sheet metal project.

CNC Precision in Sheet Metal Fabrication

CNC Precision in Sheet Metal Fabrication

Sep 03,2025

CNC machining plays a crucial role in modern sheet metal fabrication, ensuring high accuracy and repeatability for complex parts. At JOCHARMSTEEL, we utilize advanced CNC equipment for cutting, drilling, and shaping metal sheets with minimal tolerance errors.

Benefits of CNC in metal fabrication include:

High precision for intricate designs

Efficiency in mass production without compromising quality

Flexibility for custom sheet metal components

Consistency across large production batches

Our CNC capabilities allow us to deliver custom metal parts that meet strict industrial standards. Combined with skilled operators and strict quality control, we provide clients with reliable, cost-effective, and precision sheet metal fabrication.

Request your CNC sheet metal quote now and experience JOCHARMSTEEL’s expertise.

Your Trusted Partner in Sheet Metal Fabrication

Your Trusted Partner in Sheet Metal Fabrication

Dec 24,2018

Choosing the right partner for sheet metal fabrication can make all the difference in your project’s success. At JOCHARMSTEEL, we combine over 10 years of experience with advanced technology to provide customers with high-quality custom metal fabrication services.

Why Choose Us:

Precision CNC machining and advanced equipment for accuracy

Skilled welders and engineers ensuring reliable assembly

Wide range of surface finishing options: brushing, mirror polishing, powder coating, electroplating

Competitive pricing and global export experience

From metal enclosures and brackets to custom sheet metal parts, we help businesses achieve durable and cost-effective solutions. If you’re looking for a professional sheet metal fabrication supplier, JOCHARMSTEEL is your reliable choice.

Request a quote now and let’s discuss your project requirements.

•Each order is inspected and double-checked by QA as well as the Shipping Manager to insure quality and accuracy

•Strict ISO Standards are applied

•All products are under controlled for traceability

•Digital machine control are available

•Latest in quality control equipment